About Fine Bubble

Research & Development of Fine Bubble Technology by Industry-Academia Collaboration with Ariake National College of Technology

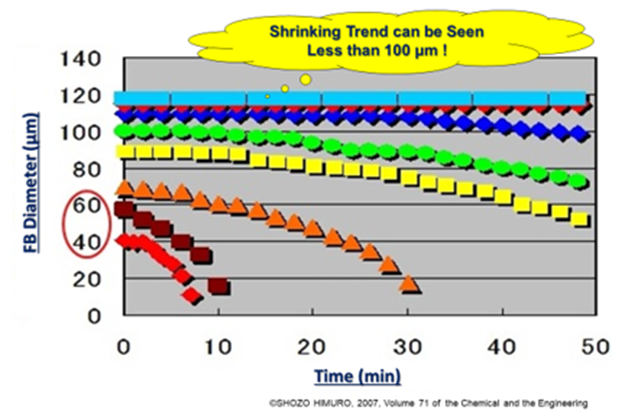

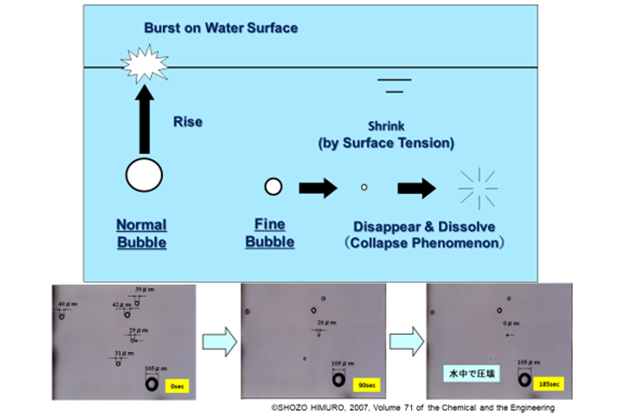

"Fine Bubbles" is used as a general term for bubbles smaller than 100 μm. Bubbles with diameters of less than 1 μm to 100 μm are classified as Micro Bubbles, and those with several tens of nm to less than 1 μm are classified as Ultra Fine Bubbles. When a fine bubble is generated in water, it behaves differently from a bubble that floats and bursts on the surface of ordinary several millimeters. Bubbles smaller than approximately 60 μm become significantly shrunk in water due to the interfacial tension between water and bubbles, and eventually crush (dissolve and disappear) in water. During this phenomenon, the physical properties of water (such as a decrease in pH and surface tension, and an increase in electrical conductivity) are changed.

Examples of the application of the fine bubble include treatment of wastewater from factories and flotation of separated SS components in the environmental field, freshness preservation and oxidation prevention in the food field, growth promotion and return increase of marine products in fisheries, and cleaning of piping and installation to washing equipment in washing field. We have developed fine bubble technology at industry-academia collaboration (Ariake National College of Technology, Fukuoka Japan) and are conducting research for demonstration.

About Fine Bubble

Bubbles of 105 μm are still present after 185 seconds, but bubbles of the size of the fine bubble region are crushed in water. (The smaller the bubble, the greater the pressure rise inside the bubble due to the effect of surface tension.)

It is believed that at the time of crushing the contained air and gas dissolve in water and that the crushing effect changes the surface tension of water.

For bubbles smaller than 60 μm, the shrinkage behavior in water becomes more noticeable as time passes.

Fine bubbles can be applied to the fields of aquaculture, agriculture, cleaning and water purification.

- Developing fine bubble generating nozzles focusing on bubbles smaller than 60 μm, which causes greater shrinkage behavior in water

- Our fine bubble generation nozzle has a simple straight structure that can be used even in muddy water environment

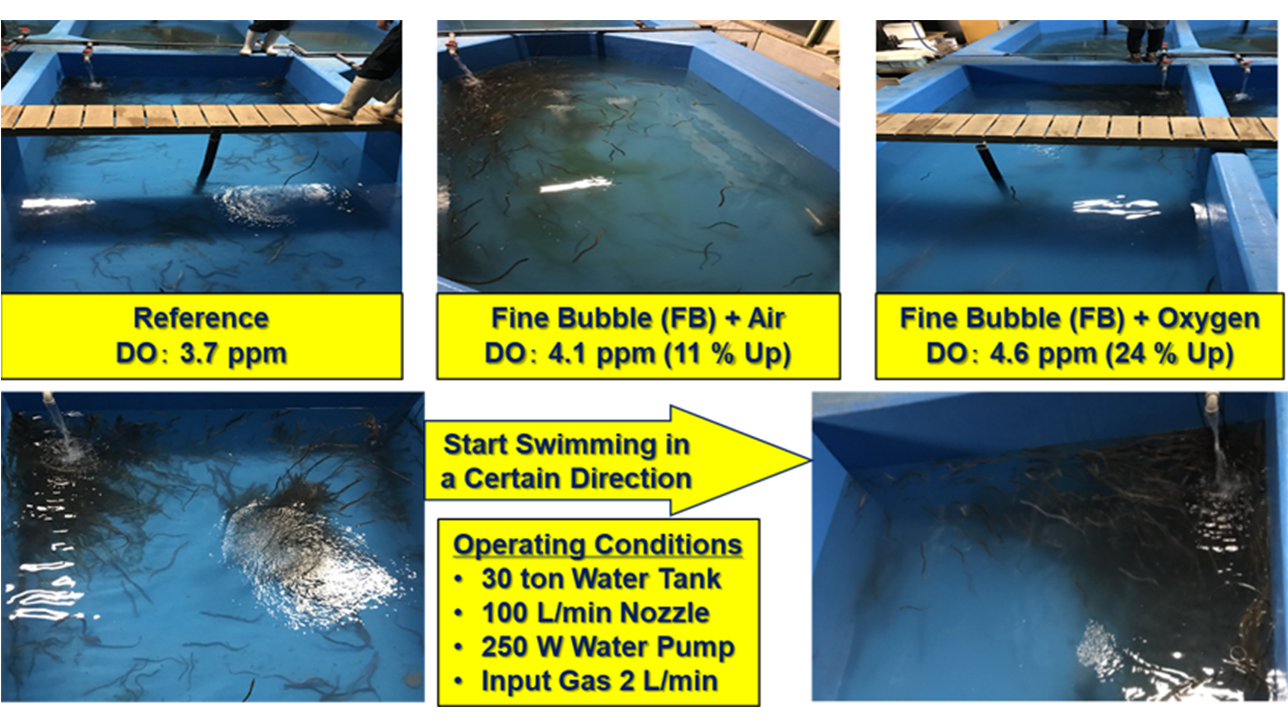

- The improvement of dissolved oxygen concentration and a sterilizing effect can be expected, depending on the type of gas contained inside the bubbles

- Compared to conventional millibubbles, the contact area of gas and liquid is wide, resulting in reducing gas consumption

- In aquafarms, it has the effect of improving survival rate and growth, leading to increasing yields and shortening the culture cycle

- Improves the cleaning effect by using it in the cleaning process

In the field of aquaculture, our project has been adopted as a survey project in Vietnam by Japan International Cooperation Agency (JICA) for the purpose of spreading nature-friendly aquaculture technology using fine bubble devices. We are investigating the improvement of aquaculture environment, the survival rate and increase of yield of farmed fish in Vietnam.

Product Line-up

Fine Bubble (FB) Nozzle Line-up MB-135S

| Fine Bubble Generating Method | Shearing System |

|---|---|

| Material | SUS316L |

| Air Introducing Hole Size | Rc 1/8 |

| Mass Weight (kg) | 0.8 |

| Flow Guide (liter/min) | 25 |

| Mounted Pump Recommended Output (W) | 60-120 |

| Length (mm) | Listed in catalog |

| Diameter (mm) | |

| Connecting Screw Size | 20A (27.2mm), 3/4 Inches |

Fine Bubble (FB) Nozzle Line-up MB-183S

| Fine Bubble Generating Method | Shearing System |

|---|---|

| Material | SUS316L |

| Air Introducing Hole Size | Rc 1/8 |

| Mass Weight (kg) | 1.8 |

| Flow Guide (liter/min) | 50 |

| Mounted Pump Recommended Output (W) | 100-150 |

| Length (mm) | Listed in catalog |

| Diameter (mm) | |

| Connecting Screw Size | 32A (42.7mm), 1*1/4 Inches |

Fine Bubble (FB) Nozzle Line-up MB-183S12

| Fine Bubble Generating Method | Shearing System |

|---|---|

| Material | SUS316L |

| Air Introducing Hole Size | Rc 1/8 |

| Mass Weight (kg) | 2.1 |

| Flow Guide (liter/min) | 100 |

| Mounted Pump Recommended Output (W) | 100-250 |

| Length (mm) | Listed in catalog |

| Diameter (mm) | |

| Connecting Screw Size | 40A (48.6mm), 1*1/2 Inches |

Fine Bubble (FB) Nozzle Line-up MB-216S

| Fine Bubble Generating Method | Shearing System |

|---|---|

| Material | SUS316L |

| Air Introducing Hole Size | Rc 1/8 |

| Mass Weight (kg) | 2.4 |

| Flow Guide (liter/min) | 300 |

| Mounted Pump Recommended Output (W) | 400-750 |

| Length (mm) | Listed in catalog |

| Diameter (mm) | |

| Connecting Screw Size | 50A (60.5mm), 2 Inches |

Fine Bubble (FB) Nozzle Line-up MB-285S

| Fine Bubble Generating Method | Shearing System |

|---|---|

| Material | SUS316L |

| Air Introducing Hole Size | Rc 1/8 |

| Mass Weight (kg) | 4.7 |

| Flow Guide (liter/min) | 500 |

| Mounted Pump Recommended Output (W) | 750-1500 |

| Length (mm) | Listed in catalog |

| Diameter (mm) | |

| Connecting Screw Size | 65A (76.3mm), 2*1/2 Inche |

Introduction of initiatives

Activation (Eels Farm)

Movement of Original Eels is so good in Fine Bubble Tank.

Increased Food Consumption & Normalization of the Mucous Membrane of Eel (Hard to get Sick)

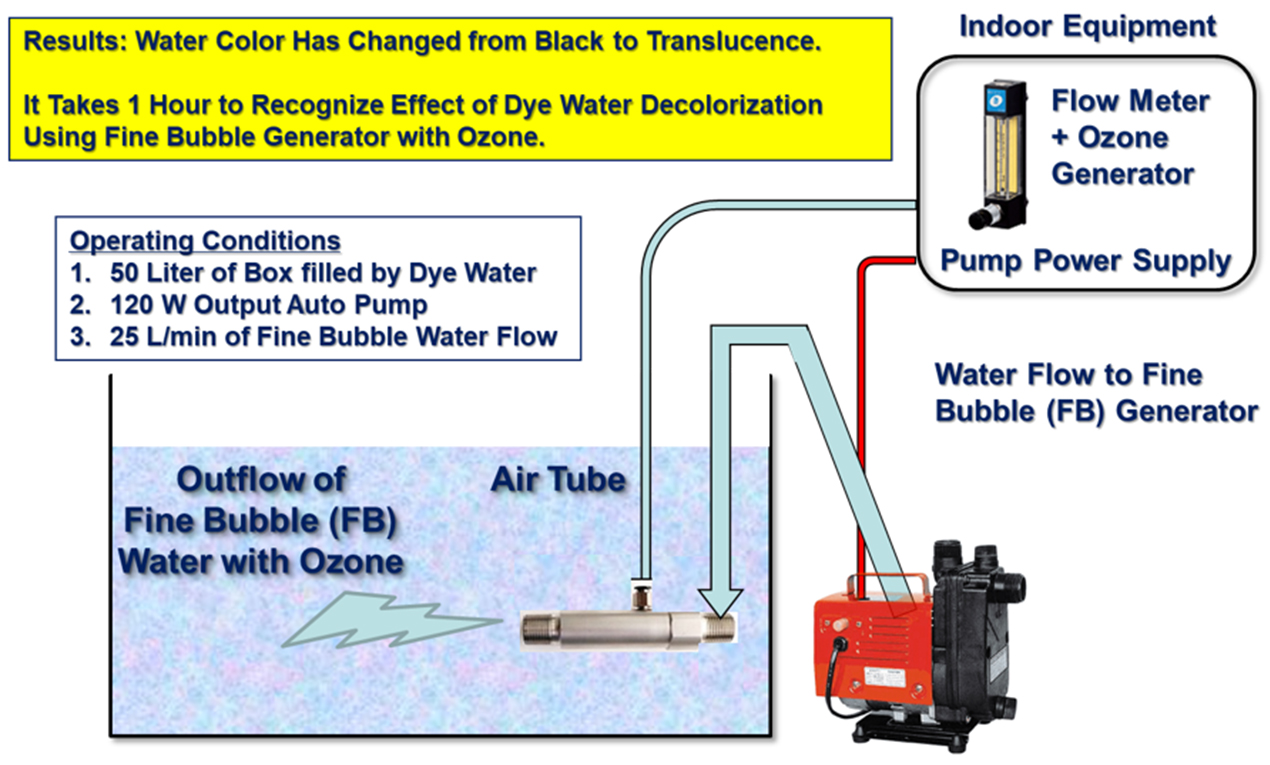

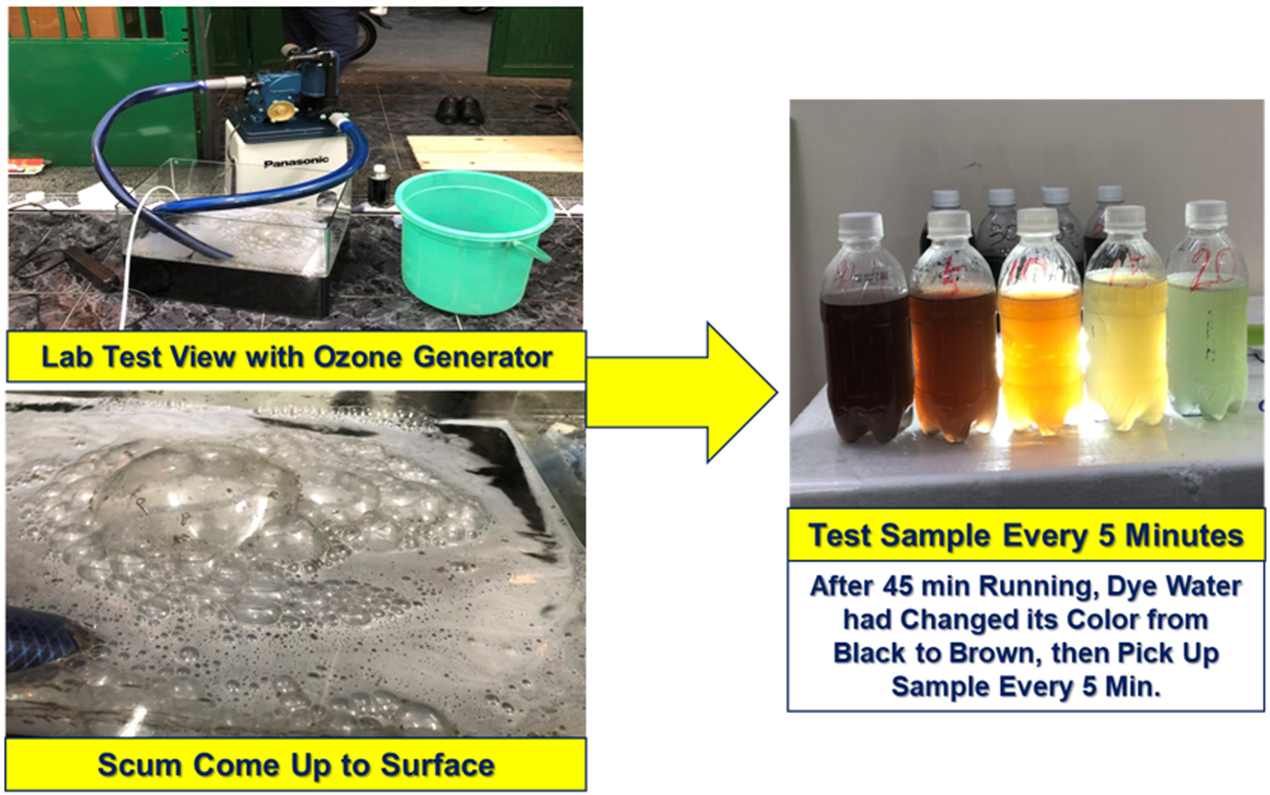

Wastewater Color Test for Wastewater Industry

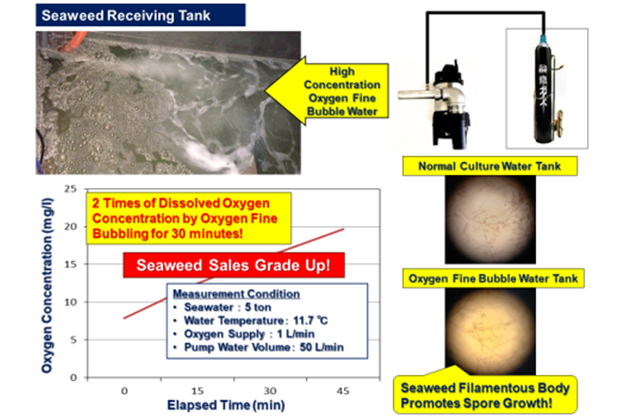

Seaweed Receiving Tank

This photo shows the bubbling treatment of seawater in seaweed receiving tanks, of a seaweed producer in Yamato-machi, Yanagawa City, Fukuoka, Japan. The use of bubbling-treated seawater resulted in the improvement in seaweed quality by several grades.

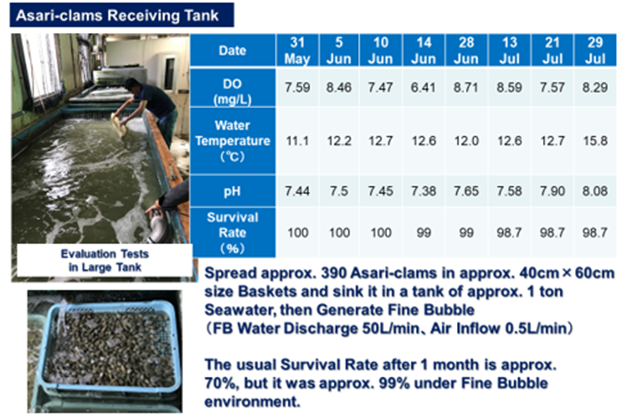

Asari-clams Receiving Tank

The changes in the survival rate of unfed Asari-clams was confirmed in receiving tanks. The conventional survival rate is 70% approxmetely, but it is a high survival rate in the environment using Fine Bubbles.

Fine Bubble Evaluation Test Site

The performing evaluation of fine bubbles is tested to improve the aquaculture environment in Vietnam. (The photos show the operation conditions at shrimp farms in Vietnam.)